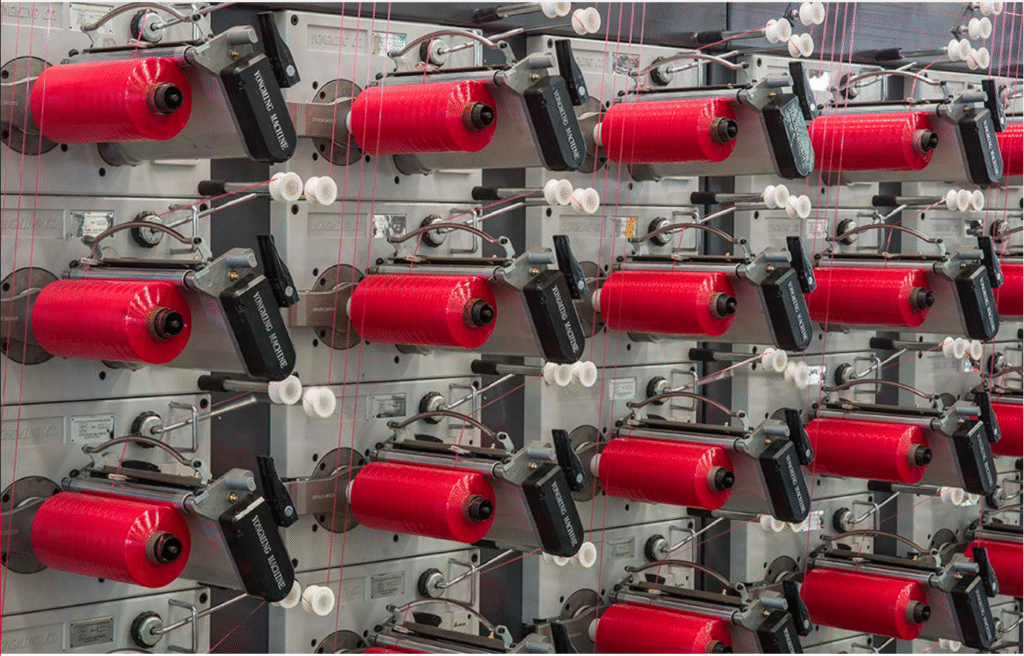

Step 2 : Winding Machines

After extrusion, the polypropylene tapes are wound onto precision bobbins using winding machines. This step ensures smooth, even rolls with minimal breakage, preparing the tapes for the next stage. Proper winding maintains uniformity and efficiency throughout the weaving process.

Home / About Us

SJJ-G230D

- Cam and bobbin driven by separate motor,keep synchronized through program

- Speed ratio between two motor can be online adjusted automatically

- Each spindle has length-control with light alarm

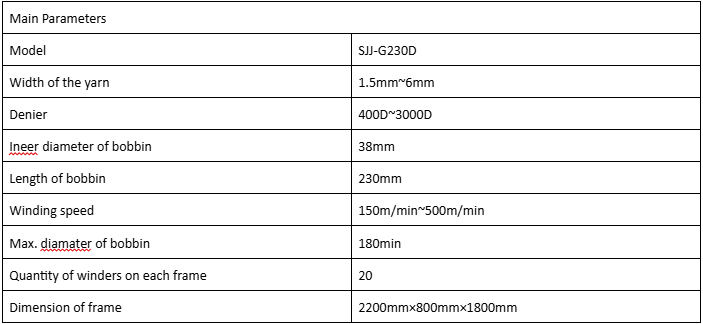

Parameters

Optional choice for the inner diameter of bobbin and the length of bobbin.

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

SJJ-G230B

- Digital tension control, optimize the form of yarn package

- Inverter control achieve the lowest power consumption

- High quality yarn ensure the perfect weaving of loom

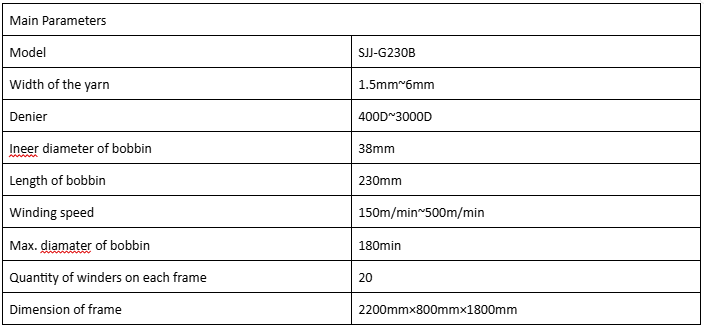

Parameters

Optional choice for the inner diameter of bobbin and the length of bobbin.

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

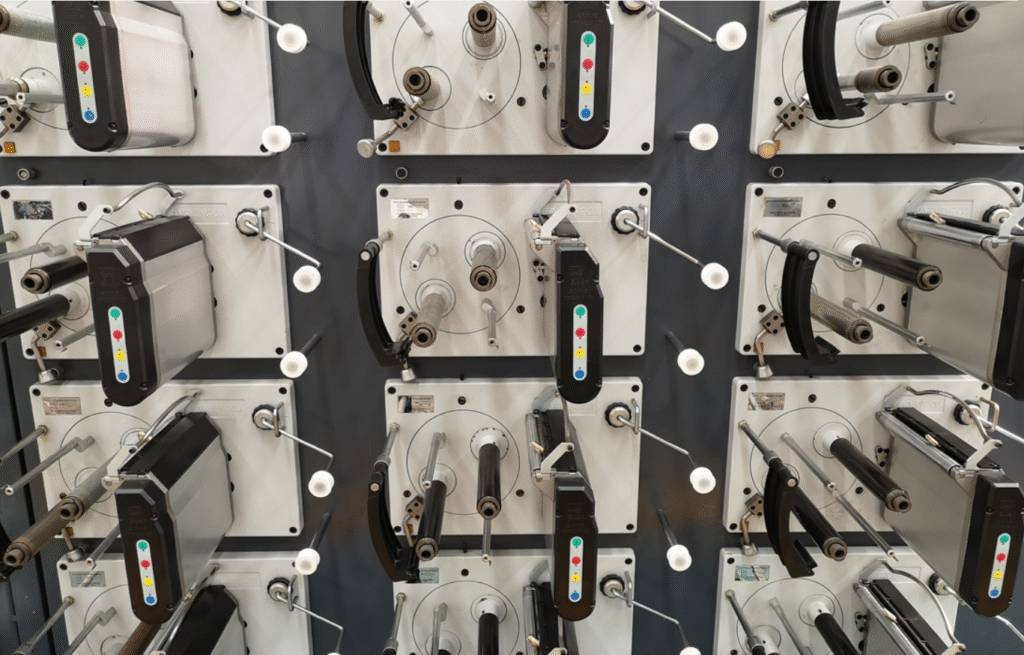

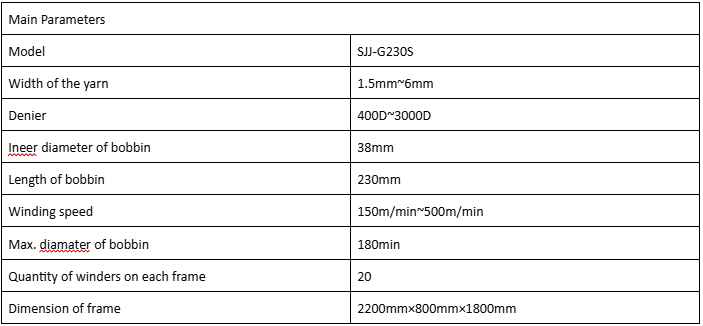

SJJ-G230S

- Auto change, save labors, high speed, high efficiency, low waste

- Make all bobbin roll in same size and tape tension stable to increase weaving process efficiency, reduce waste and tolerance of fabric width

Parameters

Optional choice for the inner diameter of bobbin and the length of bobbin.

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.