Step 5 : Printing & Conversion

Here, the coated fabric is cut, stitched, and printed with brand logos, product details, and designs. Advanced printing technology ensures clear, lasting impressions, while precision conversion guarantees strong seams and accurate sizes—ready for heavy-duty use.

Home / About Us

OG800-RWC954E

Printing Method

Double-sided 9-color (5+4) printing, completed in a single process

Production Process Flow

Unwinding → Printing → Drying → Cutting (or directly rewinding if preferred)

Main Features

Adjustable Printing & Bag Length

Length can be freely set within 1200 mm directly through the HMI touch screen, without changing rollers or gears.

High Registration Accuracy

Advanced system keeps registration error within ±0.2 mm, ensuring precise alignment and consistent print quality.

Double Sided 9 Colour Printing

One-pass 5+4 color printing starts instantly without pre-registration, producing sharp, high-quality, detailed prints.

Servo Driven Hot Cutting

Servo motor cutting system eliminates accumulated errors, delivering precise and reliable hot-cutting performance.

Main Unit Specifications

- Applicable Substrates: Cylindrical woven fabric, laminated woven fabric, paper–plastic composite woven fabric.

- Maximum Substrate Width: 800 mm

- Maximum Unwinding Diameter: ∮1200 mm

- Maximum Printing Width: 720 mm

- Printing Length: 400–1000 mm (universal size printing without changing plate roller or gears)

- Bag-Making Length: 450–1200 mm (universal size bag-making)

- Mechanical Printing Speed: 70 pcs/min

- Maximum Printing Production Speed: 60 pcs/min (at bag length of 800 mm)

- Mechanical Cutting Speed: 60 pcs/min

- Maximum Cutting Production Speed: 50 pcs/min (at bag length of 800 mm)

- Automatic Web Guiding Range: ±100 mm

- Printing Plate: 3.94 mm resin plate (recommended hardness: HV45–60)

- Ink: Slow-drying alcohol-based ink (recommended viscosity: 18–25 seconds with #2 Zahn cup)

- Solvent: Slow-drying alcohol-based solvent, 2.5–3.5 (water drying speed = 1)

- Printing Method: Double-sided 9-color, front 5 colors, back 4 colors (combinations: 5+4, 5+3, 5+2, 5+1, 4+4, 4+3, 4+2, etc.)

- Registration Adjustment: Longitudinal ±7.5 mm, transverse ±10 mm, on-line adjustment without stopping the machine

- Total Machine Weight: Approx. 10 tons

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

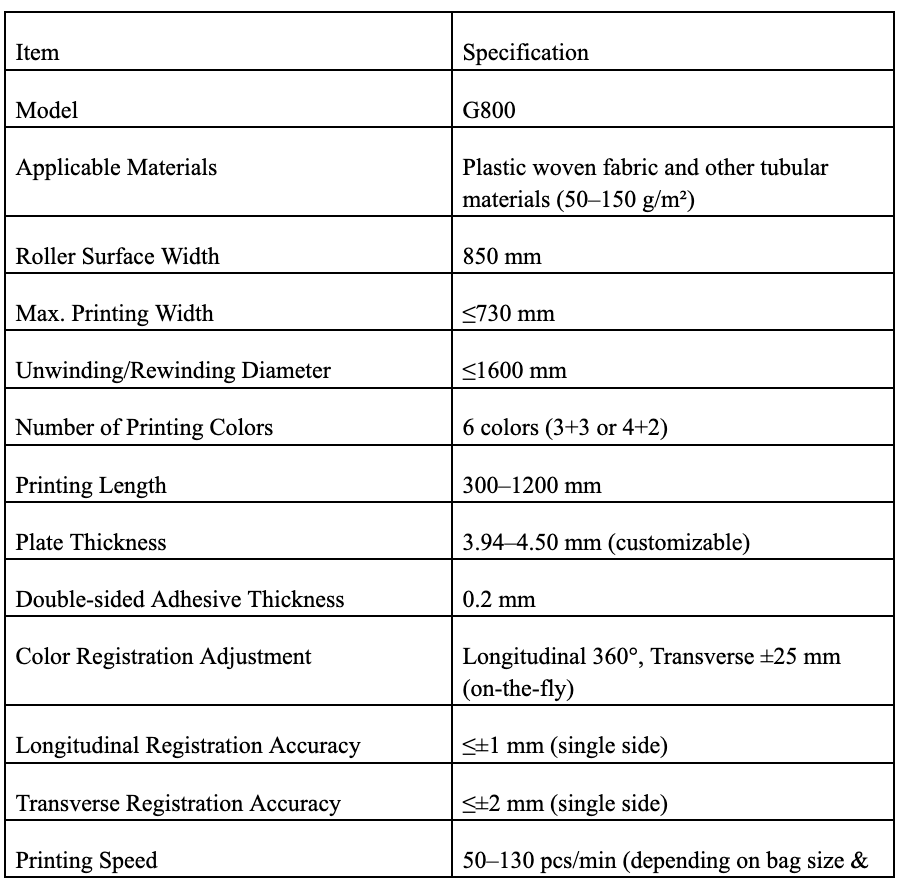

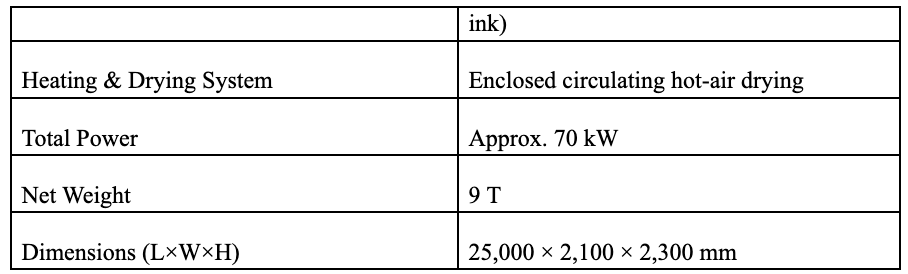

JC-G800

Technical Specifications

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

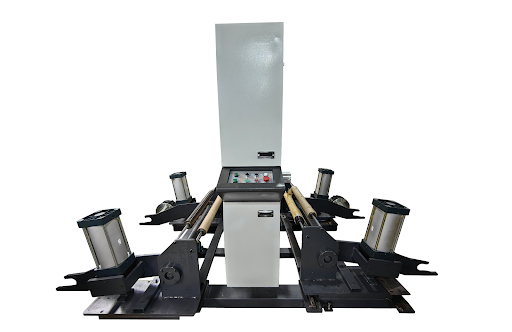

Unwinding Unit

- Equipped with a double-station unwinder.

- Uses a double-station cylinder-driven loading arm for automatic material loading. During operation, simply push the fabric roll into the loading position of the arm. Once the roll is loaded, the first station waits to connect with the second station’s fabric roll. When the roll diameter at the current station becomes smaller and reaches the set changeover size, the system automatically performs a non-stop splicing and roll change with the roll at the current station.

Pneumatic Disc Brake

- Uses signal feedback from the double-station unwinding shaft to monitor rotational speed, enabling real-time measurement and display of the roll diameter. When the roll reaches the preset changeover diameter, the system issues an alarm and automatically reduces speed, making overall machine control easier.

- Equipped with automatic stop when material breaks; tension is automatically maintained during stoppage. When restarting, the tension remains unchanged, effectively ensuring printing accuracy is not affected during start/stop operations.

- Fitted with a photoelectric servo web guiding device. An infrared photoelectric sensor detects the edge of the woven fabric as the reference point for web guiding.

- Equipped with a 3-inch air shaft (customizable upon request). The air shaft is made of aerospace-grade aluminum, making it lightweight yet highly durable.

- All unwinder operations are centrally controlled from the main control console. The unwinder’s sub-control console can also independently operate the unwinder and coordinate with the entire machine. The whole machine can be operated by a single person, with multiple control points available.

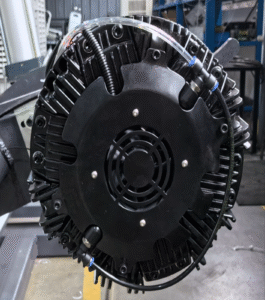

Corona Treatment Unit

(Intelligent Corona Treater)

- Equipped with an intelligent corona treater. The main unit adopts the latest integrated circuits and high-power IGBT modules, offering excellent corona discharge performance, low failure rate, and long service life.

- Controlled via a touch screen, the corona power automatically and precisely adjusts according to the equipment’s production speed. It also features power-off protection when the main equipment stops or operates at a preset low speed.Includes a discharge frame stop-and-power-off protection function. Multiple protection measures effectively prevent long-term corona sparks from damaging the woven fabric and silicone sleeve, thereby avoiding potential fire hazards. This also significantly extends the service life of the silicone layer on the corona roller, effectively reducing daily maintenance costs and the expense of consumable parts.

- Integrated design: The corona treater control cabinet is combined with the main equipment, saving space. At the same time, the high-frequency high-voltage wiring is shorter, effectively improving equipment safety.

- Front-facing observation window: Allows operators to conveniently monitor the corona treatment at any time, making it easy to adjust the treatment effect as needed.

- Oil-immersed step-up transformer: Provides excellent heat dissipation, durability, and long service life.

- Dual output function: Can output dual high-frequency, high-voltage lines for corona treatment or a single high-frequency, high-voltage line, allowing easy adjustment according to operating conditions.

- Thick-layer sensing device: Detects the approach of woven fabric joints or thick layers and automatically retracts the corona discharge frame to avoid damage to the discharge electrodes.

- Segmented electrode customization: Can be tailored according to material width for targeted treatment, ensuring excellent corona effect with minimal tensile damage to the material.

Process Deviation Correction and Intermediate Tension

- Independent intermediate process deviation correction units are installed before both front-side and back-side printing. The machine is equipped with three deviation correction systems in total, utilizing photoelectric servo-controlled mechanisms to ensure greater accuracy in printing position.

- Equipped with deviation correction controllers featuring an intuitive display, enabling operators to easily monitor and make adjustments.

- Incorporates advanced tension control technology, delivering high precision in tension regulation.

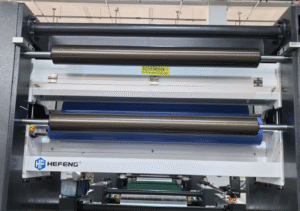

Printing Unit

- The printing unit adopts a modular structure, configured with a front 3-color and back 3-color modular printing group (or front 4-color and back 2-color).

- The main wall plates and chassis of the printing unit adopt a thickened and reinforced structure. After undergoing aging treatment, they are precisely machined using a large-scale machining center, effectively ensuring the equipment’s accuracy and the machine’s stability during long-term high-speed operation.

- The printing groups are powered by first-class domestic brand Inovance Technology, with independent servo motor drives (electronic shaft synchronous transmission). A coaxial direct-drive structure is used, with the servo motor directly connected to the reducer, eliminating gears for higher transmission efficiency and easier maintenance.

- An ink transfer method combining a ceramic anilox roller with a rubber roller is employed. The side ends adopt a sealed structure, effectively preventing ink misting, splashing, and leakage.

- An upper-web path frame is adopted, with a centrally positioned pre-print traction unit. This reduces the web threading length and shortens the distance from the traction unit to the printing group, thereby improving printing accuracy and operational stability.

- Equipped with an automatic inking system, utilizing a pneumatic diaphragm pump for continuous ink circulation.

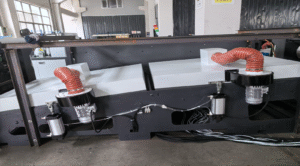

Drying Unit

- Independent recirculating, closed-type drying ovens are provided separately after front-side printing and after back-side printing.

- Each oven adopts an internal heat-insulation double-panel structure, offering easy maintenance and high energy efficiency.

- Each drying oven is equipped with temperature control, using temperature control modules for independent regulation, ensuring convenient maintenance.

Rewinding Unit

back-to-back rewinder

- Rewinding power is driven by an asynchronous gear motor, offering quick synchronous response, high precision, high transmission efficiency, and lower energy consumption.

- The roll-change air shaft (spare rewinding shaft) is automatically lifted by a flip arm, rotating into position for roll change. This ensures safe and effortless operation.

- A servo flying-knife system is used for web cutting, with a pneumatic arm pressing the roll-change shaft for web splicing, enabling fully automatic, non-stop roll change under optimal operating conditions.

- The rewinding shaft uses a 3-inch aluminum air shaft (customizable to customer requirements) to meet the production process requirements of square-bottom heat-seal bag-making machines. The air shaft is made of aerospace-grade aluminum, offering light weight and high strength.

- Equipped with an electric lifting mechanism for the up-and-down movement of the rewinding air shaft, ensuring that one person can easily replace it.

Control Unit

(Touch Screen Control Panel)

- The equipment adopts an electronic shaft architecture, with all drive power provided by servo systems. A motion controller manages each servo system and key associated operations, integrating tension control, corona treatment, and centralized control into one system. This ensures fast response speed, high control precision, excellent synchronization, and truly intelligent, integrated operation.

- The human–machine interface (touch screen) allows data setting and modification. The main screen displays the machine’s operating status, including production line speed, shift output, total output, single roll length, and total length. Additional screens can display operating parameter monitoring/recording, historical data records, and alarm notifications.

- Unwinding tension, post-printing tension, and rewinding tension are all centrally controlled by the motion controller, with real-time display of each tension value, enabling clear visibility of the production status and easy operation.

- The central master control console and each sub-control station are linked for coordinated group control. Each sub-control station can operate its own independent functions. Multiple emergency stop buttons are provided, along with a remote-control panel for wireless operation.

- The main UI screen on the touch panel can simulate and display the images of each functional unit of the equipment, as well as all set parameters and operating statuses of these units, providing highly user-friendly operation.

- The main electrical components used in the system are compliant with CE certification standards. The electrical control cabinet is designed and manufactured to meet IP21 safety protection level requirements.

- The electrical control system features an IoT (Internet of Things) architecture, allowing online modification of touch screen settings and access to production data from mobile devices or PCs. It also supports copying and storing historical production data via USB flash drive, facilitating operation and management.

JLMPM ( Taiwan)

Specification

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

NRP/2012-C

- Optional Equipment

- Imprint Arrangement 6+0, 5+1, 4+2, 3+3 colors combinations

- Production Output : 120 meter / min

- Based on our original Reel to Reel Printing Line which had produced more than 10 years, we have further up-grade our machine. The New Reel to Reel Printing Line is a whole new design, the main improvements we need to emphasize are: Equipped Gear Box on Each Printing Station, These Gear Box Can 360X Oline Print Registration While the Machine in Running. Equipped Overhead Drying Oven.

- Gear-Box equipped on each Printing Station, which, can perform online 360 rotation, in facilitating the conduct of micro adjustment required on individual station Imprint-Artwork Registration, under Non-Stop Operation.

- Gear-Box equipped on each Printing Station, which, can perform online 360 rotation, in facilitating the conduct of micro adjustment required on individual station Imprint-Artwork Registration, under Non-Stop Operation.

Main Feature

- Reel to Reel Printing Line is the most efficient way for the PP woven bag printing, and capable of two side printing on the bag in the one process, based on the current market demand, we are able to provide 12 colors(each side 6 colors) Reel to Reel Printing Line.

- Our Reel to Reel Printing Line provide the best printing quality with high output (up to 120 meter / minute) and only one operator required. Decreasing the printing cost to the lowest. It is the most wisdom choice for printing.

Major Specification

- Equipped Gear Box On Each Printing Station, These Gear Box Can 360° Online Print Registration While the Machine is Running.

- Enhanced Drying System for Quickly Drying

- Diameter of Unwinding Cloth 1200mm Maximum Applicable

- Width of Unwinding Cloth 350-850mm Applicable

- Printing Repeat Length 500-1300mm

- Production Output 120 meters/minute Max.

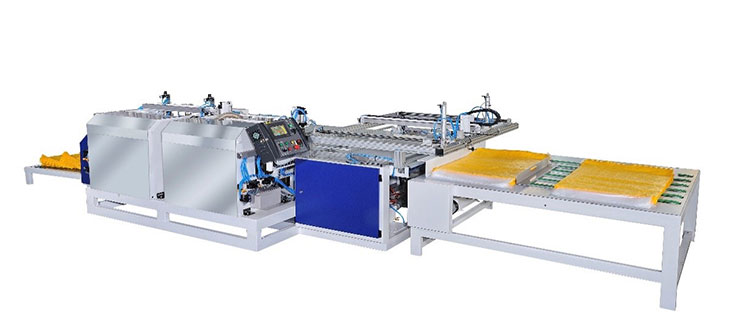

CS-2012

- In today's competitive packaging market, our state-of-the-art PP woven bag making machine sets the benchmark for efficiency, precision, and reliability. As a leading manufacturer in the industry, we combine innovative design with advanced engineering to deliver a solution that not only meets but exceeds the expectations of modern production lines.

Unmatched Performance and Precision

- Advanced Servo Motor Technology: Equipped with two high-performance servo motors, our machine delivers precise control and rapid responsiveness, ensuring a seamless manufacturing process.

- Optimized Bag Transfer System: The integrated 90° bag transfer gripper enhances operational flow, reducing downtime and maintaining a continuous production cycle.

- Intuitive Display Interface: The user-friendly display screen operation interface simplifies machine setup and monitoring, allowing operators to adjust settings and monitor performance in real time.

- High Production Output: With a production capacity of 32-45 bags per minute, our machine is designed to meet high-volume demands while maintaining consistent quality.

Industry Ecpertise and Commitment to Quality

- At the core of our manufacturing philosophy is a commitment to excellence and continuous innovation. Our team of experts works closely with clients to tailor our PP woven bag making machine to specific production needs, thereby enhancing operational efficiency and product quality. This customer-centric approach has established our reputation as a trusted partner in the packaging industry.

Main Feature

- Equipped Two Servo Motors

- Equipped 90 degree Bag Transfer Gripper

- Display Screen Operation Interface

- High Product Output (32-45 Bag / min)

- Custom-made designs are available

Major Specification

- Diameter of Unwinding Cloth 1400 mm Maximum Applicable

- Width of Unwinding Cloth 300-850 mm Applicable

- Cutting Length 500-1400 mm Adjustable

- Production Output 32-45 bags / minute

- Sewing Unit New Long DKN-3BP (4500 rpm)

- Length Accuracy Within ±1 mm Range

- Cutting Knife High Quality Alloy Steel Cutter With Tubular Heater,

JLCSM-SERIES

Specification

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

CIS-2016

Main Feature

- Fully Automatic In-Line Process for Liner Inserting-Cutting-Sewing.

- Applied for both functions: 1. Liner can be fully sewn with PP Woven Bag. 2. Liner also can not be sewn / loose inside PP Woven Bag.

- Without inserting a liner, the machine can process for normal Cutting-Sewing function.

- Saving Manpower Hugely.

- With Excellence Quality & Stable Performance.

Major Specification

- Bag Width (With Liner Insert) 400-700 mm Applicable

- Bag Length (With Liner Insert) 500-1100 mm Applicable

- Production Capacity 20 Bags Per Minute.

- PE Film Width +20 mm (Bigger PE Film Width)

- Bag Width (Without Liner Insert) 400-800 mm Applicable

- Bag Length (Without Liner Insert) 450-1400 mm Applicable

- Production Capacity 20 ~ 30 Bags Per Minute.

- Diameter of Unwinding Cloth 1200 mm Maximum,

Top-Hem

- Avalaible for Woven Bag

- With Liner Inserted Bag / And Also Normal Bags Without Liner Insertion.

- With Laminated Woven Fabric /And Also Non-Laminated Woven Fabric.

- Main Feature :

- Auto Bag Top Alignment & Hemming of Liner Inserted PP Woven Bag. (Automatic Bag Top Alignment for PP Woven Bag and Inner PE Liner)

- Bag Top can be Folded or Non-Folded.

- Experiencing the Clean Process of Bag Top Hemming. Largely Reducing Hand-Touching on the Bag Top Area.

- Servo Driven Gripper Type Conveying Delivery, Ensuring Neat & Steady Bag Delivery.

- Saving Manpower and Saving Cultivated Training for Skilled Manual Operators.

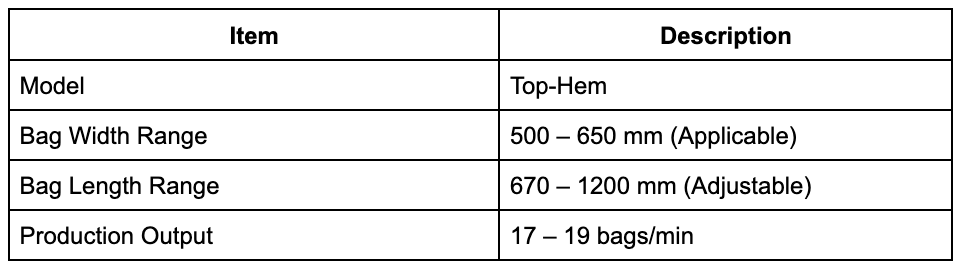

Specification