Step 1 : Extrusion

The extrusion process is the foundation of woven plastic sack production. High-quality polypropylene granules are melted and transformed into strong, uniform tapes. This step ensures consistent durability, flexibility, and reliability of the material—forming the backbone for every stage that follows in the production line.

Home / About Us

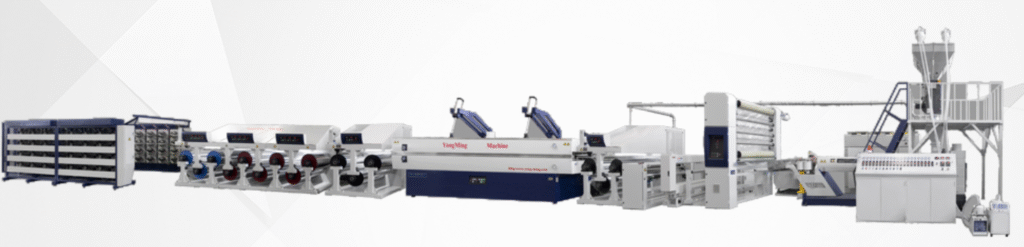

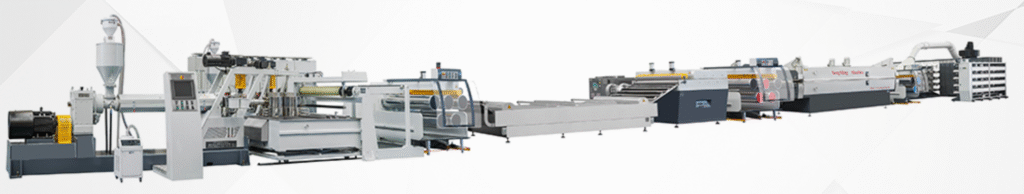

SJPL-G

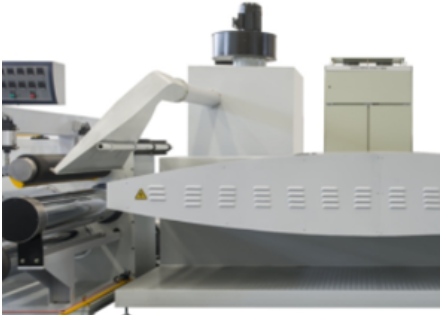

- SJPL-G series high speed plastic extrusion tape line is specially design for PP and HDPE with high quality and excellent performance

- Available for production various PP & HOPE tapes with high quality and requirement (low denier, high denier, fibrillation tape, folded tape, etc)

- High precise T-Die: simulating extrusion and one-off process molding by CNC guarantee the tape quality

- Special design stable flow device and water remove system create the condition for high speed production

- Eight Godets $440mm stretching & shaping get high tenacity and stables shaping effect for tapes

- Intelligentized control system with function of data save, fault alarm, central control, easy operation

- Inverter winder-tape tension control stable by inverter, bobbin formed smooth surface, high speed up to 550m/min.

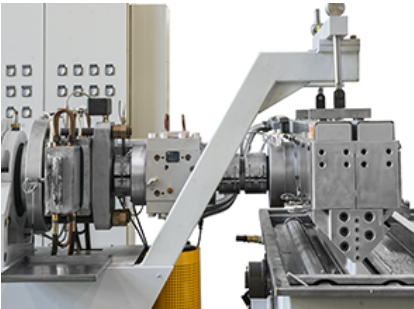

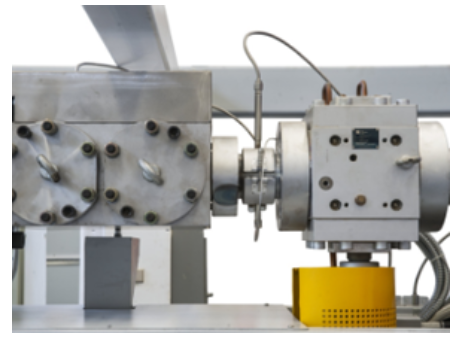

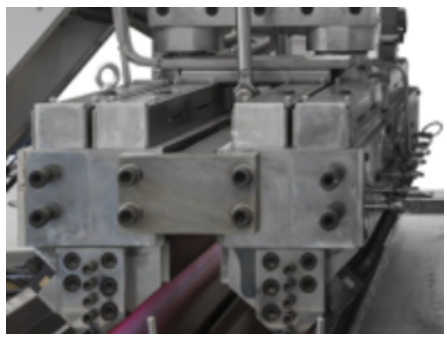

High Precision T-Die

Advanced CNC processing ensures stable extrusion and consistent molding, guaranteeing excellent tape quality, uniform thickness, and efficient production with reduced material waste.

Intelligentized Control System

PLC-based controls allow simple operation, quick fault detection, and reliable monitoring, improving safety, reducing downtime, and ensuring smooth machine performance during production.

Stretching & Fixing Device

This device enhances tape strength and stability by providing uniform tension and shaping, resulting in durable, high-quality tape with consistent dimensional accuracy.

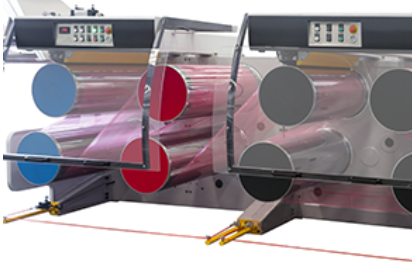

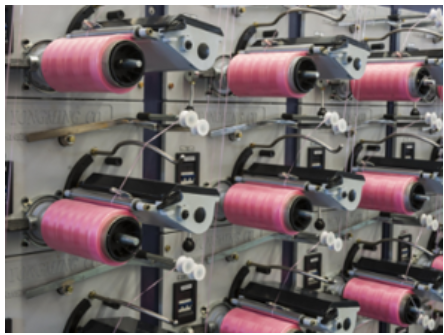

Inverter Winder

Inverter-controlled winding units maintain stable tension, creating smooth bobbins with precise torsion. High-speed output up to 550m/min ensures reliable and consistent tape quality.

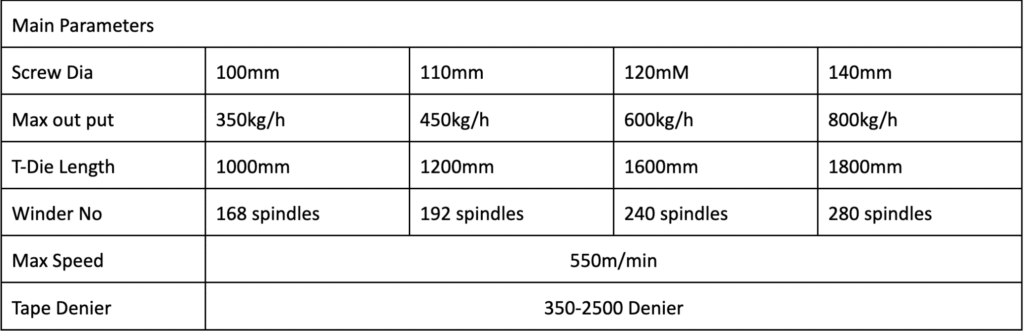

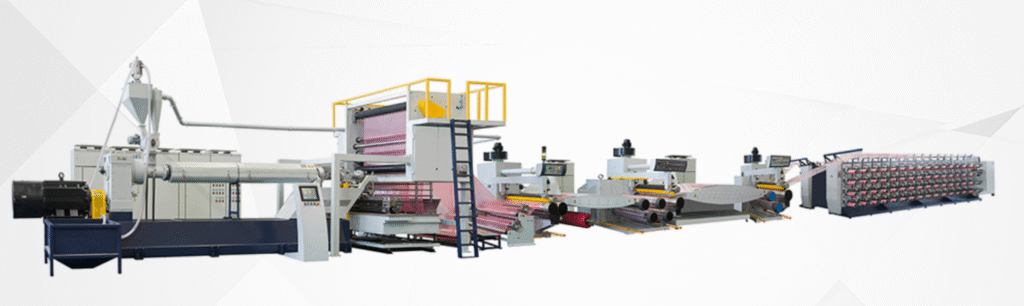

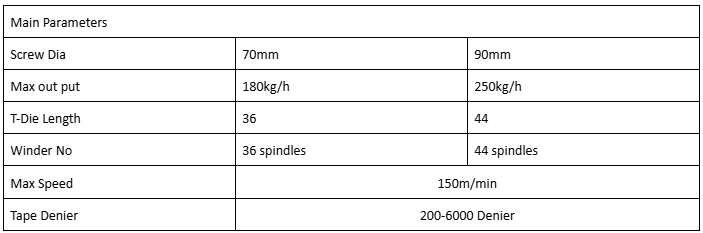

Parameters

Composed By

- Material Loader

- Extruder

- Auto Change Filter

- Half-off Device

- Water Tank

- Film Take Up

- Slitting Device

- Stretching Unit

- Safety Shield

- Edge Online Recycling System

- Winder

- = Standard

- Dosing Blender

- Auto-Die

- DST Motor

- Melt Pump

- Second Filtering

- Three-Folding Device

- Film Thickness Measurement

- Hot Air Oven

- Fibrillation Device

- Static Eliminator

- Water Chiller

- = Option

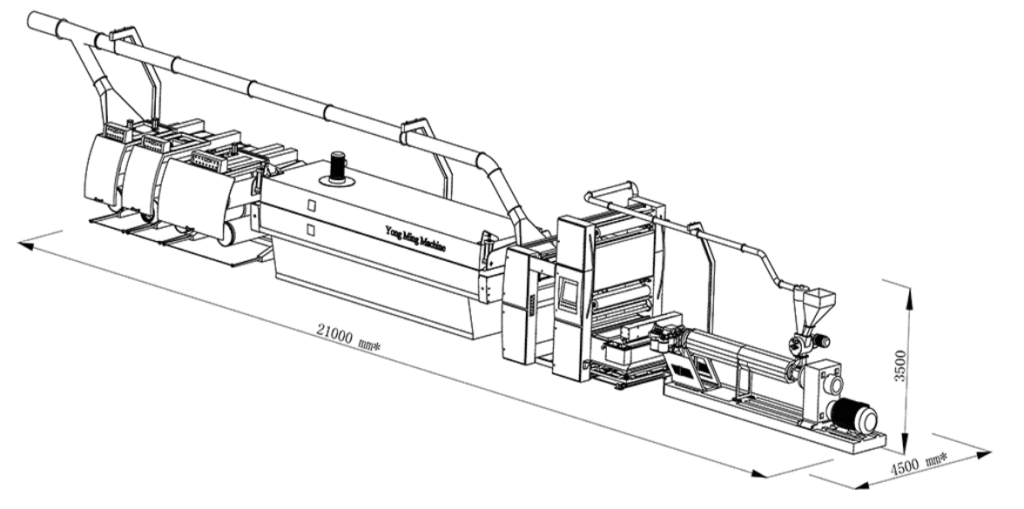

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

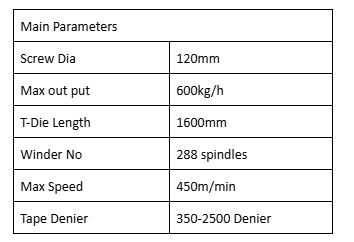

- Plastic carpet backing tape extrusion line is special design for high quality tape with good performance and low shrinkage

- Available for different various tapes with high requirement on low shrinkage such as tufted carpet PP tape, artificial grass backing fabric, second backing fabric, axminster carpet backing welt yarn.

- Multiple working position dosing blender for various material with function of data save

- Special design stable flow device and water remove system create the condition for high speed production

- Intelligentized control system with function of data save, fault alarm, central control, easy operation

- Low noise and heat-resistant blower and ATC hot air circulation system maximizes heating efficiency. Each performance of hot air oven reach top level in domestic

- Filtrator make the tapes soft, adopt pulley belt driving to speed up/down synchronized. Transmission steady, low noise and easy operation

- High precise hot godets offer ensurance for tape shrinkage control

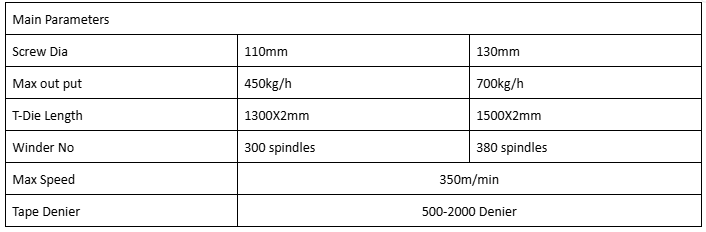

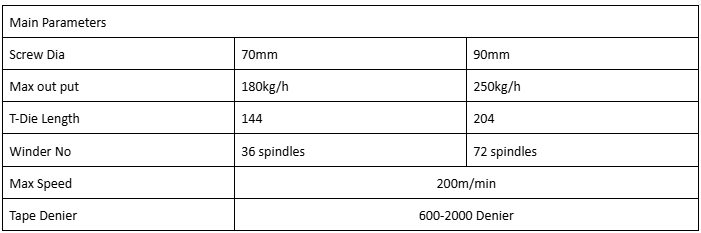

Parameters

Composed By

- Extruder

- Stretching Unit

- Nine Godets Hot Annealing Unit

- Waste Yarn Collector

- Inverter winder

- T-Die

- Tater Tank

- Film Take Up, Slitting, Haul-Off Unit

- Waste Edge Online Recycling System

- Hot Air Oven

- = Standard

- Dosing Blender

- Material Loader

- Melt Pump

- Static Mixer

- DST Motor

- Thermostatic Control System For Water Tank

- Shaping Device

- Film Thickness Measurement

- Fibrillator

- Water Chiller

- = Option

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

HDPE

HDPE Tarpaulin Extrusion Tape Line is special design for HDPE fabric, Tarpaulin. Adopt double Die and double side hot plate structure for low denier PE tapes with high production capacity 15ton/day and low power consumption ≤500KW·H. Intelligentized control system with function of data save, fault alarm, central control, easy operation

Melt Pump System

The melt pump eliminates extrusion fluctuations, ensuring steady film thickness, improved stability, and consistent quality output for reliable and precise production performance.

High Precision T-Die

CNC-simulated extrusion with one-off molding produces dual films of high quality at once, delivering uniform thickness and efficient production reliability

Double Heating Plate Stretching & Annealing Unit

This unit stretches and anneals two films simultaneously, enhancing efficiency, improving film stability, and ensuring superior performance for the next processing stage.

Big Size Bobbin Winder

Large bobbins meet weaving requirements with even tape tension and smooth packaging, ensuring reliable performance and high efficiency in downstream processes.

Parameters

Composed By

- Material Loader

- Extruder

- Filter

- T-Die

- Water Tank

- Film Take Up & Half-Off

- Slitting Unit

- Edge Film Online Recycling System

- Stretching Hot Plate

- Stretching Roller

- Hot Annealing Plate

- Cooling Roller

- Waste Tape Collecter

- Static Electric Eliminator

- Winder

- = Standard

- Fibrillator

- Mixer With Drying

- Water Chiller

- = Option

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

SJYL-Z

- SJYL-Z Plastic monofilament extrusion line is specially designed for high strength PP and HDPE.

- High strength monofilament

- Equal density

- Lowest consumption

- Best Economic benefit

- Intelligentized control system with function of data save, fault alarm, central control, easy operation

- Available belt for: jumbo bag, fish net, artifical grass, rope

High Precise Fiber Spraying Board

Using low-dump-flow channel design, this board ensures uniform extrusion and molding, delivering highly even monofilaments with consistent quality and reliable performance.

Stretching Device

Large-diameter rubber rollers provide strong drive force for stretching, ensuring stable production of high-strength monofilament yarn with excellent consistency and efficiency.

Stretching Water Tank

The specially designed tank maintains accurate water compensation and stable temperature, ensuring even conditions that enhance stretching quality and monofilament uniformity.

Empaistic Device

This optional device softens monofilaments through empaistic treatment, improving flexibility and performance, particularly in the production of high-strength belts and related applications.

Parameters

Composed By

- Material Loader

- Extruder

- Auto Change Filter

- Water Tank

- Haul-Off Unit

- Hot Water Tank

- Water Remover

- Stretching Unit

- Winder

- = Standard

- Dosing Blender

- Melt Pump

- Static Mixer

- Hot Air Oven

- Shaping Device

- Embossing Device

- DST Motor

- Thermostatic Control System For Water Tank

- Multi-Shaping Device

- Water Chiller

- = Option

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

SJDS

- SJDS Plastic Artificial Turf Extrusion Line SJDS series Plastic Artificial Turf Extrusion Line is special design for high quality artificial turf yarn

- Available : PP, HDPE, LLDPE for production artificial turf yarn

- Multiple working position dosing blender for various material with function of data save

- Intelligentized control system with function of data save, fault alarm, central control, easy operation

- Patent technology:sufficient patents of cross, S , arch, rhombus and U type yarn production

- High precise DIE : multiple hole with flow balancing technology to offer ensurance the good quality for single yarn

Parameters

Composed By

- Material Loader

- Extruder

- Die

- Stretching Unit

- Hot Air Oven

- Shaping Unit

- Water Yarn Collector

- Winder

- Water Tank

- Haul-Off Unit

- Hot Water Stretching Device

- Water Remove System

- = Standard

- Dosing Blender

- Auto Change Filter

- DST Motor

- Melt Pump

- Hot Air Oven

- Water Chiller

- Static Mixer

- Shaping Device

- Water Chiller

- = Option

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.