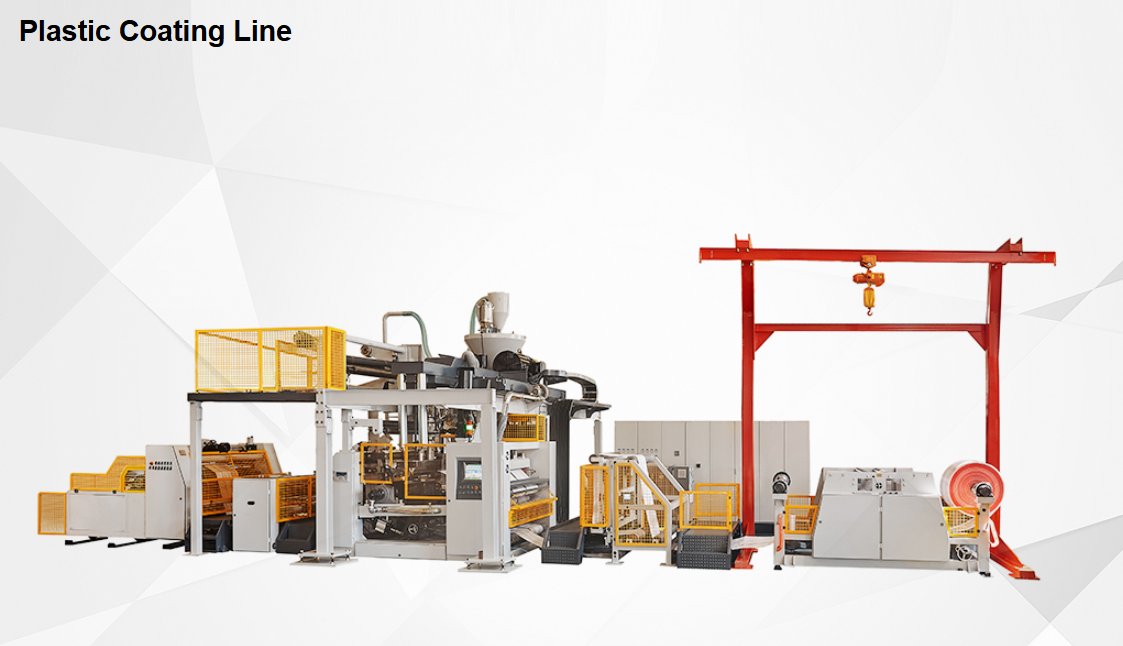

Step 4 : Coating

The woven fabric is coated with a protective layer to improve durability, resistance to moisture, and strength. This coating enhances the material’s ability to withstand harsh conditions, ensuring sacks remain reliable during storage and transport.

Home / About Us

SJFM-Z

- Flat fabric single side coating & BOPP laminating, Aluminum foil laminating, kraft paper, and non-woven fabric laminating

- Running speed: 220m/min

- HMI central control, high level of automation, easy operation

- Non-stop changing fabric roll, winding length setting auto cut

- Flexible reliable photoelectrical edge trimming system, accurately control the edge size

- Waste edge online recycling system, reduce material waste, increase production efficiency

Edge Trimmer System

Flexible and reliable photoelectric trimming system that ensures precise edge size control for consistent results.

High Precision T-Die

CNC-based extrusion simulation with one-step molding guarantees stable film quality and accurate thickness.

Friction Winding

Equipped with pneumatic cutting and non-stop roll change, minimizing waste while boosting efficiency.

Online Waste Recycling

Continuous edge crushing and direct recycling into the hopper, keeping production clean and sustainable.

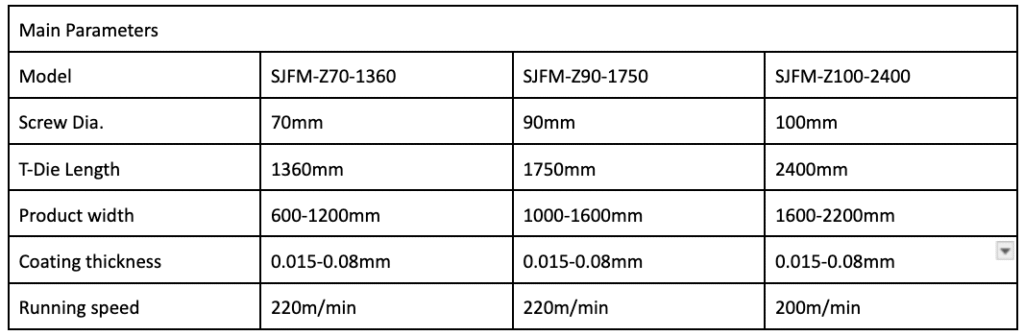

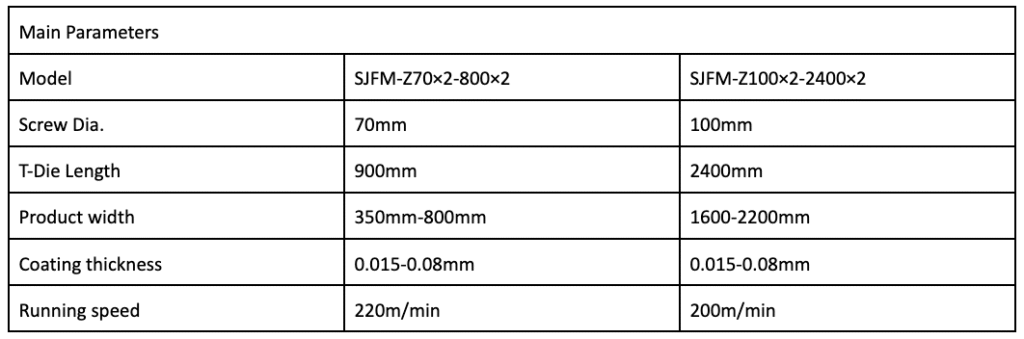

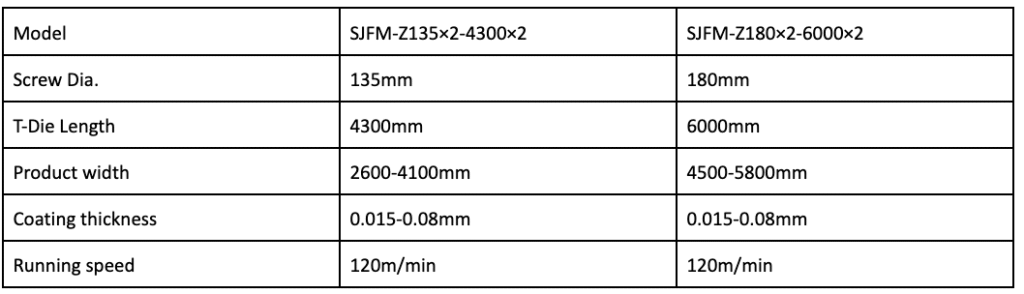

Parameters

Composed By

- Unwinder

- Epc

- Laminator

- Edge cutter

- Winder

- Hang Movable Extruder

- Unwinder Hoist

- Online Edge/waste film recycling system

- = Standart

- Waste Squeezing device

- Corona Pretreating System

- Other Unwinder

- Alumunium Side Platform

- U-turn device

- 2ns extruder

- 2nd laminator

- Water Chiller

- Dosing Unit

- Static Eliminator

- Water Chiller

- = Option

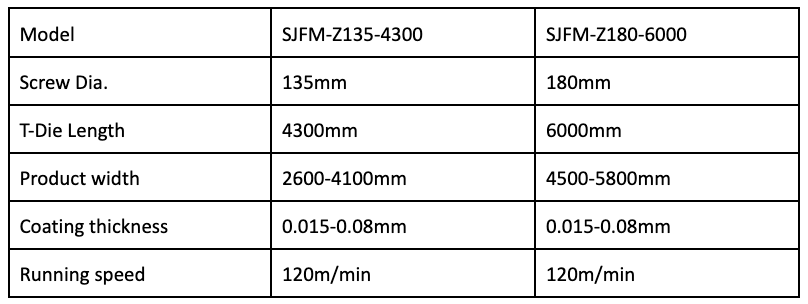

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

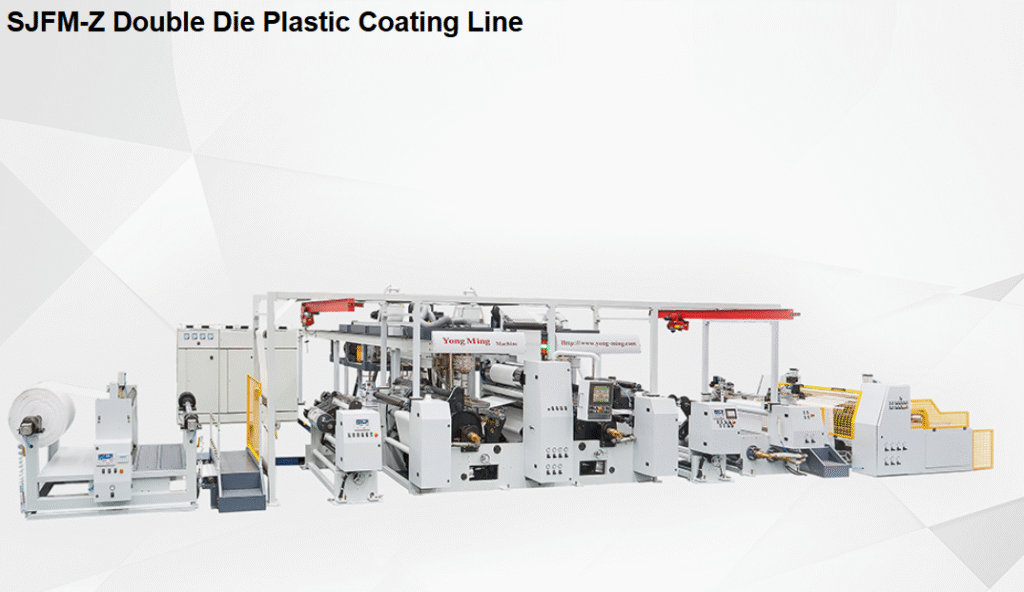

SJFM-Z Double Die

SJFM-Z Double Die Plastic Coating Line reach the waterproof and anti-seepage fucntion through laminating the surface of PP/HDPE woven fabric and alll kinds of industrial fabric

Available for small woven bag double side coating & BOPP laminating, HDPE Tarpaulin fabric coating, flat fabric single side coating & BOPP laminating, Aluminum foil laminating, kraft paper, and non-woven fabric laminating

- Running speed: 220m/min

- Non-stop changing fabric roll, winding length setting auto cut

- Flexible reliable photoelectrical edge trimming system, accurately control the edge size

- Waste edge online recycling system, reduce material waste, increase production efficiency

Intelligent Control System

Centralized HMI touch screen for speed, temperature, and alarm records, ensuring easy operation and real-time monitoring.

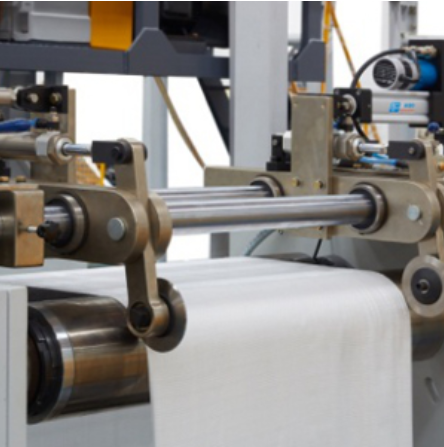

Fabric Un-Winder

Automatic roll changing with correction and tension control for stable running at high speed and maximum efficiency.

Bopp Un-Winder

Non-stop roll change with automatic film registration, tension detection, and control to maintain precise film quality.

Edge Trimmer System

Reliable photoelectric trimming system that flexibly adjusts and accurately maintains the edge size during production.

Parameters

Composed By

- Unwinder

- un-winder for BOPP film

- Un-winder crane

- Epc

- Laminator

- Extruder

- OPP Registering system

- Edge cutter

- Winder

- HMI control system

- = Standard

- Corona

- Water Re-move device

- Waste edge online recycling system

- Other Unwinder

- Dosing Blender

- Water Chiller

- = Option

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

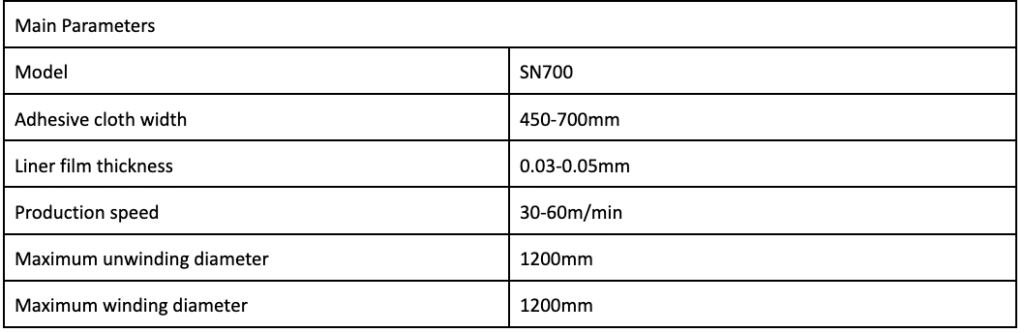

SN700

- SN700 Woven bag liner compounding line is specially designed for bringing the plastic film inside the tubular woven fabric, reaching the function of waterproof and moisture-prevent . Available for chemical bag, sugar bag, fire-hose,

- Special helix air track supplies equal hot air onto the fabric surface, ensures the sufficiency melting and adhesion between EVAPE film and the inner side of tubular fabric

- Unwinding and haul-off unit: for unwinding , haul-off and sealing

- A special design cooling path and chilling roller are used together to give a fast cooling after lamination. The winding will be in normal temperature condition and fabric roller will be without internal stress

- Winding tension stable and fabric roll smooth

Perfect Cooling System

Specially designed cooling path with chilling rollers provides rapid cooling after lamination, keeping rolls stress-free.

Unwinding & Holding Unit

Automatic system for unwinding, holding, and sealing fabric rolls, ensuring stable operation and reliable performance.

Advance Heating Oven

Helix air track delivers uniform hot air, ensuring proper melting and strong adhesion between EVA-PE film and fabric.

Stable Tension Winding

Torque motor precisely controls winding tension, guaranteeing smooth operation and consistent roller quality every time.

Parameters

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.