Step 3 : Circular Loom

In this stage, the wound tapes are woven into durable tubular fabric using circular looms. The process creates strong, flexible cloth with consistent structure—perfect for heavy-duty woven sacks. The quality of weaving determines the final sack’s load capacity and performance.

Home / About Us

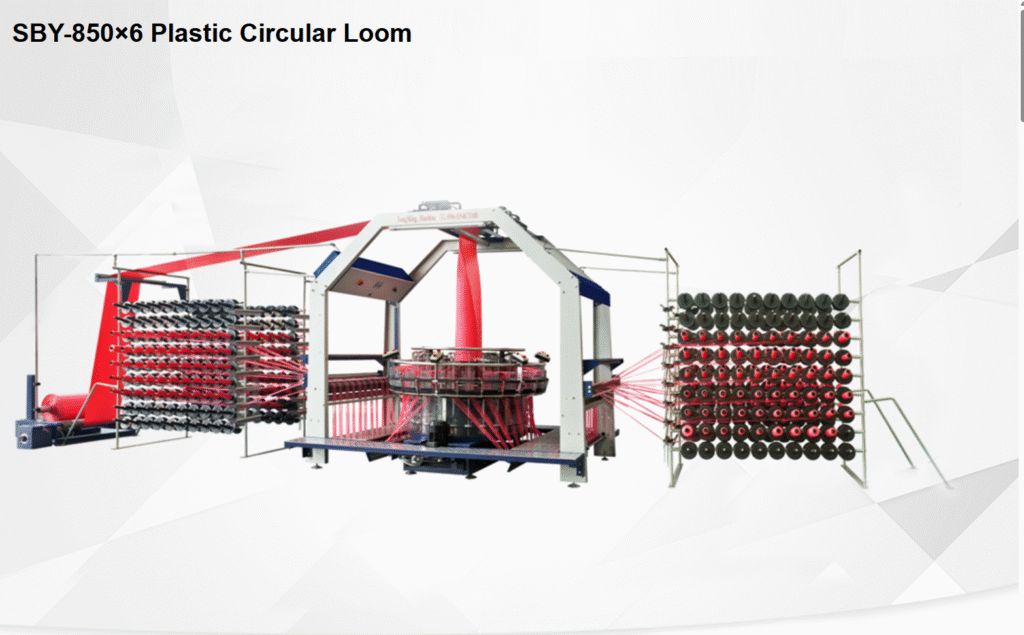

SBY-850×6

- SBY-850×6 Plastic circular loom is specially designed for the high quality wide tube or flat fabric by PP or HDPE Available: chemical bag, cement bag, rice bag, flour bag, shopping bag etc

- Oil spraying lubrication, stable running performance

- Weft end detecting system

- HMI central control, easy operation

Small Cam Structure

Equipped with an oil-spraying lubrication system, ensuring stable running performance, reduced friction, and longer service life of the loom.

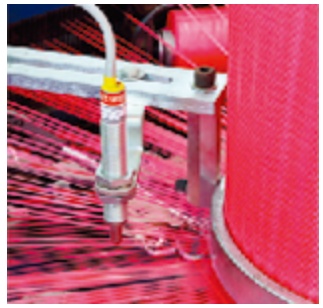

Weft Finished Detecting System

Automatically detects color differences between the weft bobbin and tape; once nearly empty, the loom stops to reduce material waste and improve efficiency.

Weft Break Detecting System

Operated through precise magnetic signal transmission, offering flexible, accurate, and reliable control during weaving for stable performance.

Accurate Servo Haul-Off System

Adopts advanced position control technology to provide precise weft compensation, avoiding yarn huddling or shortages during stop-and-start operations.

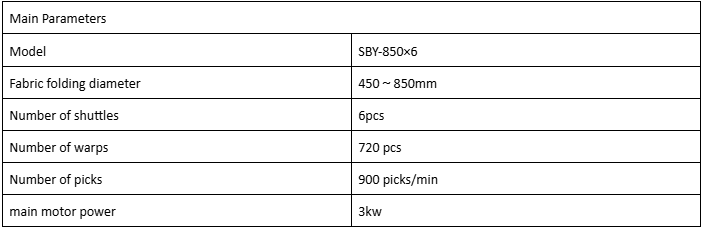

Parameters

Composed By

- Main Portion

- Creel Frame

- Warp Break Detecting System

- Weft Break Detecting System

- Central Drive System

- Fabric Take Up System

- Size Ring

- Control System

- Winder

- = Standard

- Warp Feed System

- Slitting And Expander

- Inner Line Film Unwinder

- Gesseting Device

- The Second Winder

- = Option

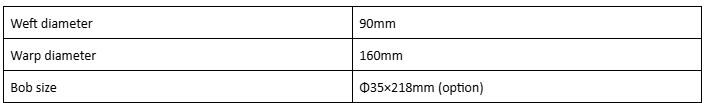

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

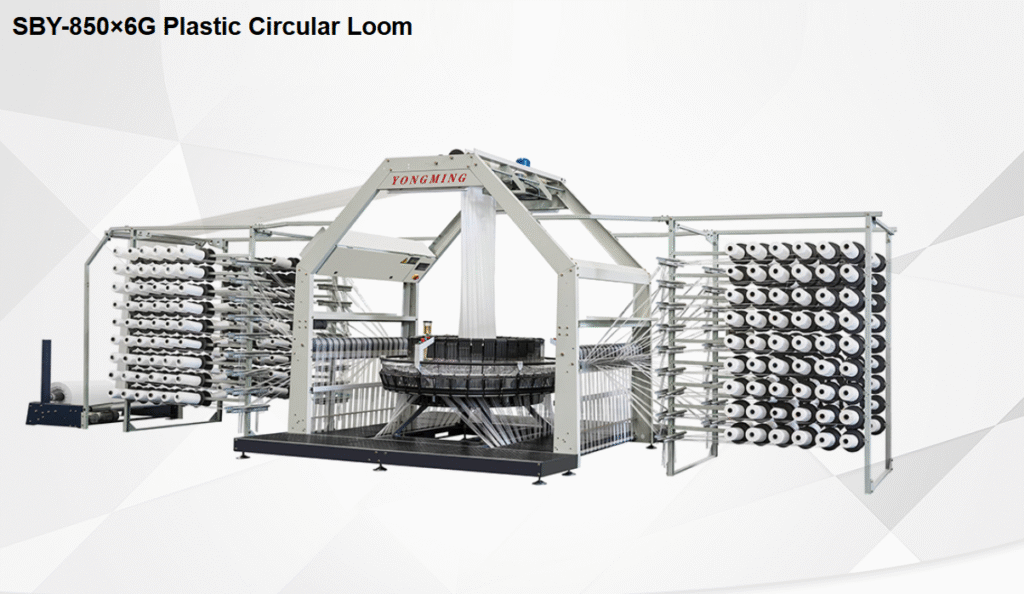

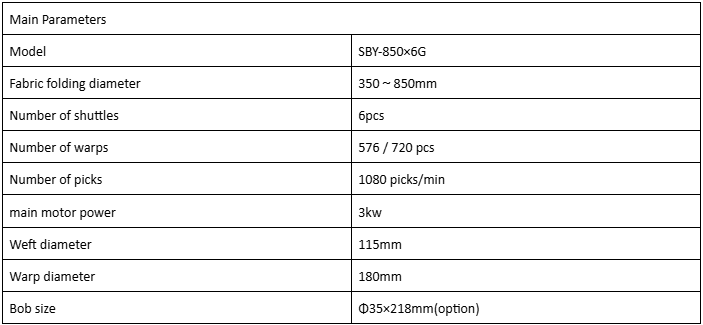

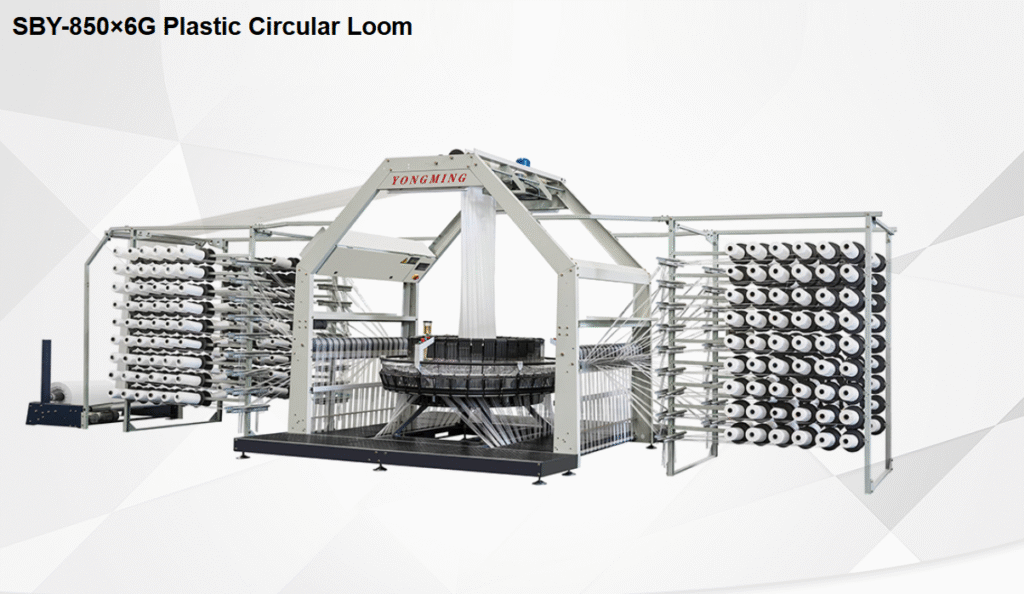

SBY-850×6G

- SBY-850×6G Plastic circular loom is specially design for the high quality wide tube or flat fabric by PP or HDPE Available: chemical bag, cement bag, rice bag, flour bag, shopping bag etc Plate cam with Grommet band & heddle wire structure, running stable, low noise, low consumption and high efficiency

- Weft break & end detecting system

- Warp feed system

- HMI central control, easy operation

Human-Machine Interface

Main motor, fabric lifting motor, and warp feeding motor adopt inverter control. The advanced HMI ensures smooth operation, precise adjustment, and user-friendly handling.

Warp Feeding System

Designed to adjust warp tension on both sides according to fabric weight. This minimizes weaving width variations, ensuring consistent quality and stable performance.

Weft Breakage & Finished Detecting System

Breakage detection uses magnetic signals for accurate and reliable control. Finished detecting stops the loom automatically when the weft tape is nearly exhausted.

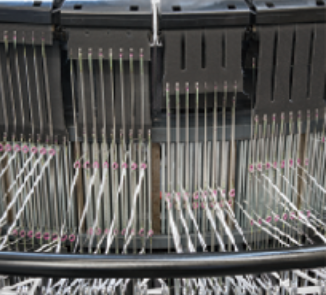

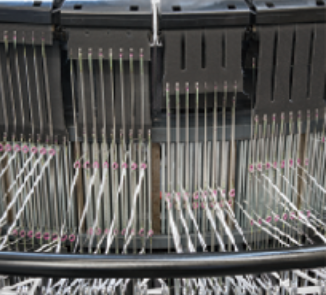

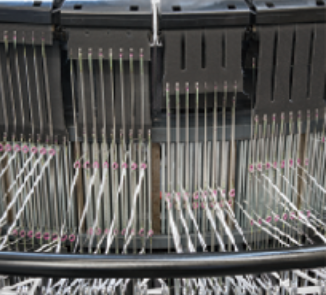

Grommet Band & Wire Heald Structure

Made of high-strength, durable materials combined with wire healds. Provides stable weaving performance, reduced noise, and long service life of the machine.

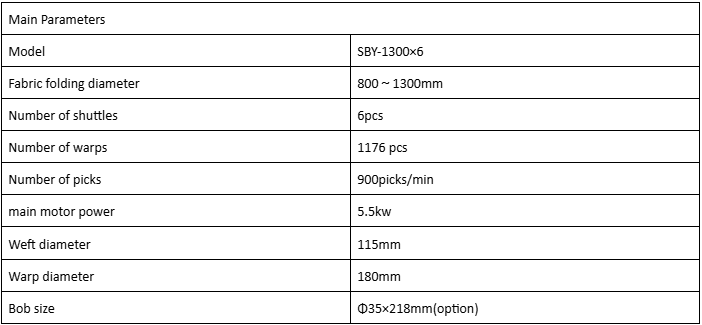

Parameters

Composed By

- Main Portion

- Creel Frame

- Warp Break Detecting System

- Weft Break Detecting System

- Central Drive System

- Fabric Take Up System

- Size Ring

- Control System

- Winder

- Warp Feed System

- = Standard

- Slitting And Expander

- Inner Line Film Unwinder

- Gesseting Device

- The Second Winder

- DST Motor

- Winder With Load Cell

- = Option

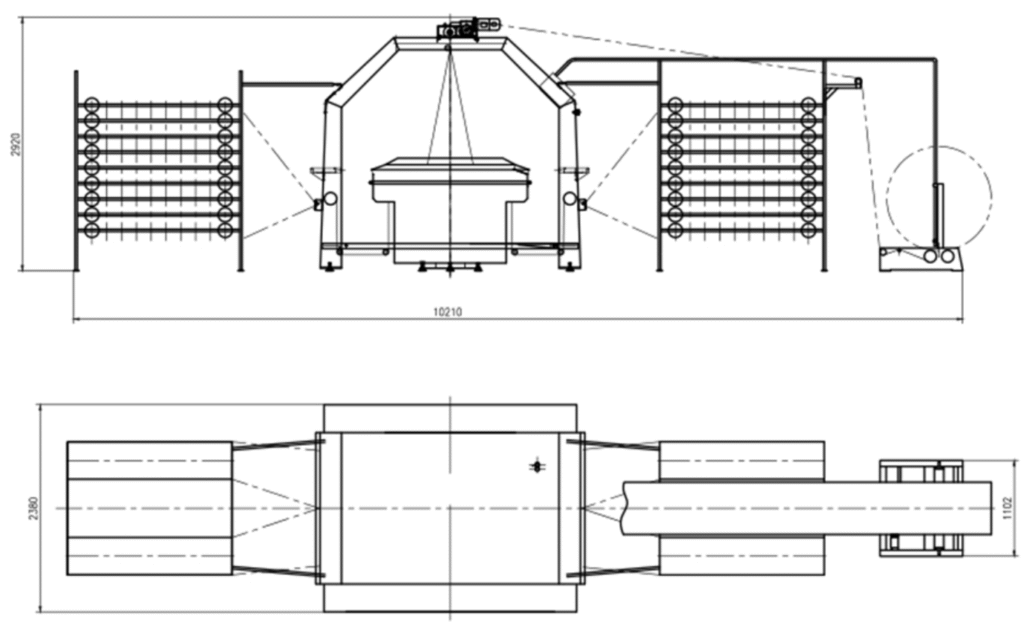

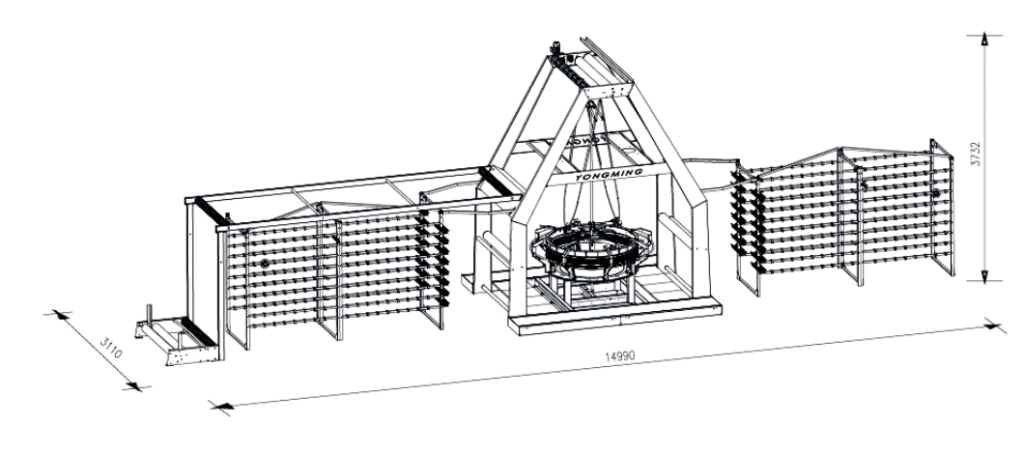

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

SBY-1300×6S

- SBY-1300×6SPlastic circular loom is specially design for the high quality wide tube or flat fabric by PP or HDPE, Available : Chemical bag, Jumbo Bag, Tarpaulin etc.

- Plate cam with Grommet band & heddle wire structure, running stable, low noise, low consumption and high efficiency

- Weft break & end detecting system

- Warp feed system

- HMI central control, easy operation

Human-Machine Interface

Main motor, fabric lifting motor, and warp feeding motor adopt inverter control. The advanced HMI ensures smooth operation, precise adjustment, and user-friendly handling.

Warp Feeding System

Designed to adjust warp tension on both sides according to fabric weight. This minimizes weaving width variations, ensuring consistent quality and stable performance.

Weft Breakage & Finished Detecting System

Breakage detection uses magnetic signals for accurate and reliable control. Finished detecting stops the loom automatically when the weft tape is nearly exhausted.

Grommet Band & Wire Heald Structure

Made of high-strength, durable materials combined with wire healds. Provides stable weaving performance, reduced noise, and long service life of the machine.

Parameters

Composed By

- Main Portion

- Creel Frame

- Warp Break Detecting System

- Weft Break Detecting System

- Central Drive System

- Fabric Take Up System

- Size Ring

- Control System

- Winder

- Warp Feed System

- = Standard

- Slitting And Expander

- Inner Line Film Unwinder

- Gesseting Device

- The Second Winder

- = Option

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

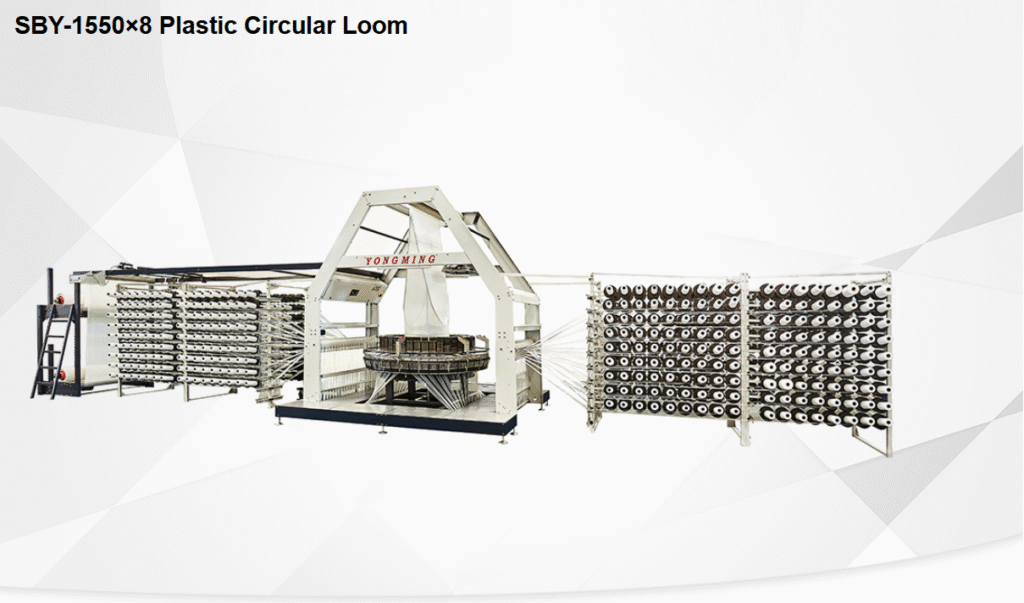

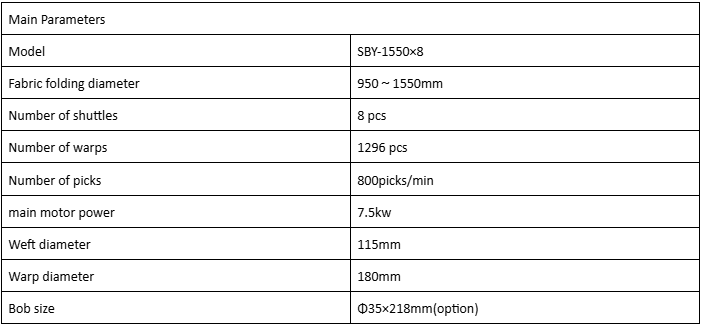

SBY-1550×8

- SBY-1550×8Plastic circular loom is specially design for the high quality wide tube or flat fabric by PP or HDPE Available : Chemical bag, Jumbo Bag, Tarpaulin etc.

- Plate cam with Grommet band & heddle wire structure, running stable, low noise, low consumption and high efficiency

- Weft break & end detecting system

- Warp feed system

- HMI central control, easy operation

Human-Machine Interface

Main motor, fabric lifting motor, and warp feeding motor adopt inverter control. The advanced HMI ensures smooth operation, precise adjustment, and user-friendly handling.

Warp Feeding System

Designed to adjust warp tension on both sides according to fabric weight. This minimizes weaving width variations, ensuring consistent quality and stable performance.

Weft Breakage & Finished Detecting System

Breakage detection uses magnetic signals for accurate and reliable control. Finished detecting stops the loom automatically when the weft tape is nearly exhausted.

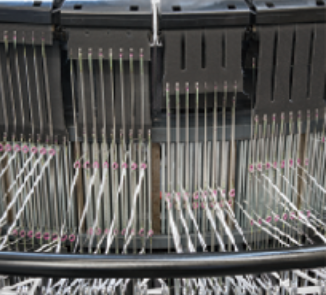

Grommet Band & Wire Heald Structure

Made of high-strength, durable materials combined with wire healds. Provides stable weaving performance, reduced noise, and long service life of the machine.

Parameters

Composed By

- Main Portion

- Creel Frame

- Warp Break Detecting System

- Weft Break Detecting System

- Central Drive System

- Fabric Take Up System

- Size Ring

- Control System

- Winder

- Warp Feed System

- = Standard

- Slitting And Expander

- Inner Line Film Unwinder

- Gesseting Device

- The Second Winder

- = Option

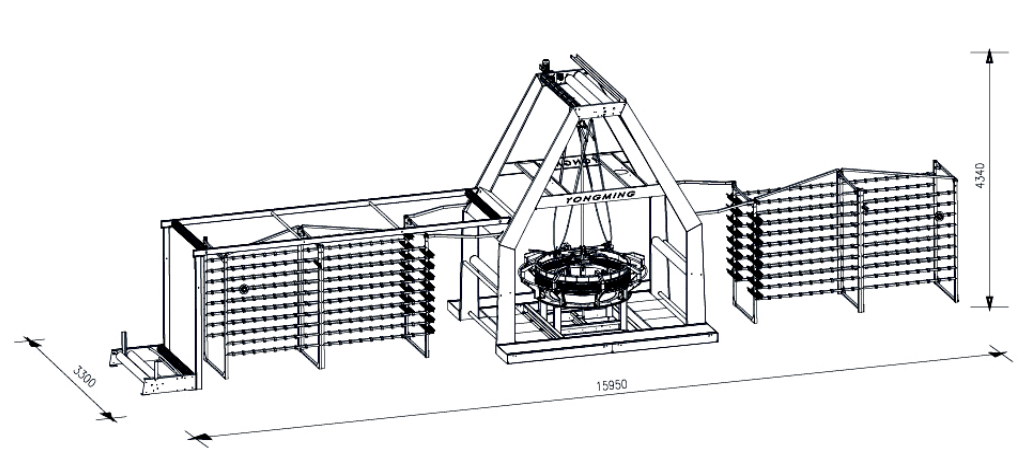

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

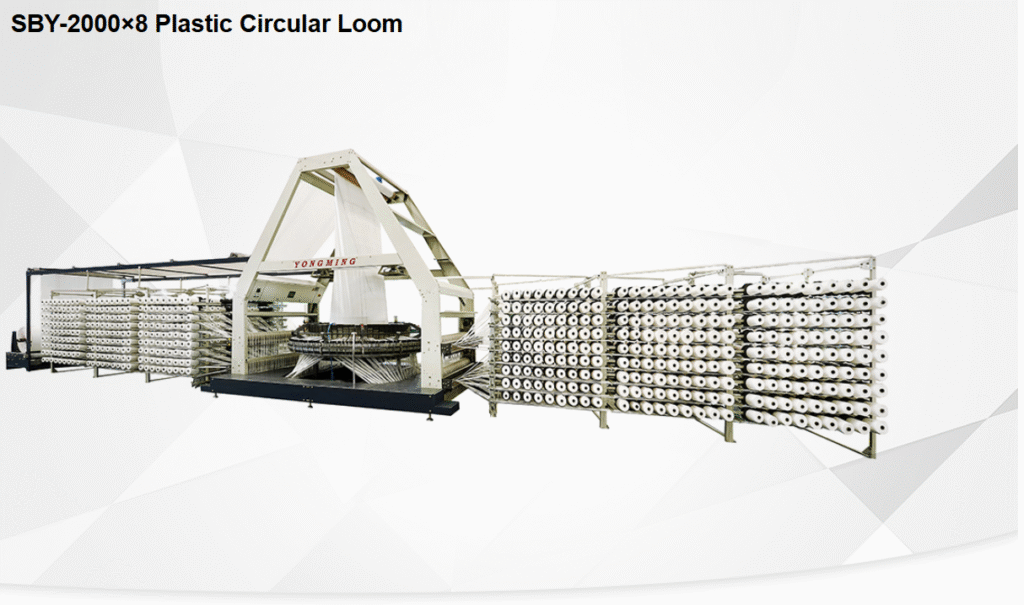

SBY-2000×8

- SBY-2000×8 Plastic circular loom is specially design for the high quality wide tube or flat fabric by PP or HDPE Available : Jumbo Bag, Tarpaulin Geo Textile, etc.

- Plate cam with Grommet band & heddle wire structure, running stable, low noise, low consumption and high efficiency

- Weft break & end detecting system

- Warp feed system

- HMI central control, easy operation

Human-Machine Interface

Main motor, fabric lifting motor, and warp feeding motor adopt inverter control. The advanced HMI ensures smooth operation, precise adjustment, and user-friendly handling.

Warp Feeding System

Designed to adjust warp tension on both sides according to fabric weight. This minimizes weaving width variations, ensuring consistent quality and stable performance.

Weft Breakage & Finished Detecting System

Breakage detection uses magnetic signals for accurate and reliable control. Finished detecting stops the loom automatically when the weft tape is nearly exhausted.

Grommet Band & Wire Heald Structure

Made of high-strength, durable materials combined with wire healds. Provides stable weaving performance, reduced noise, and long service life of the machine.

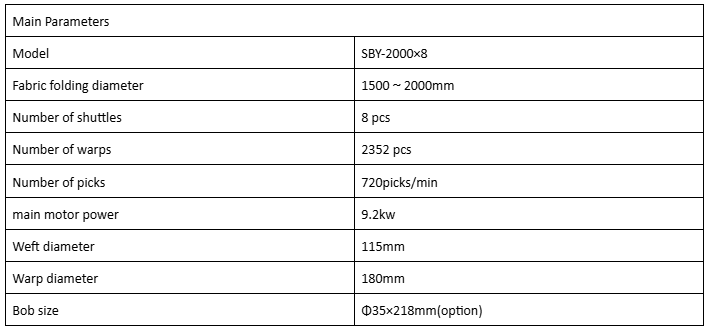

Parameters

Composed By

- Main Portion

- Creel Frame

- Warp Break Detecting System

- Weft Break Detecting System

- Central Drive System

- Fabric Take Up System

- Size Ring

- Control System

- Winder

- Warp Feed System

- = Standard

- Slitting And Expander

- Inner Line Film Unwinder

- Gesseting Device

- The Second Winder

- = Option

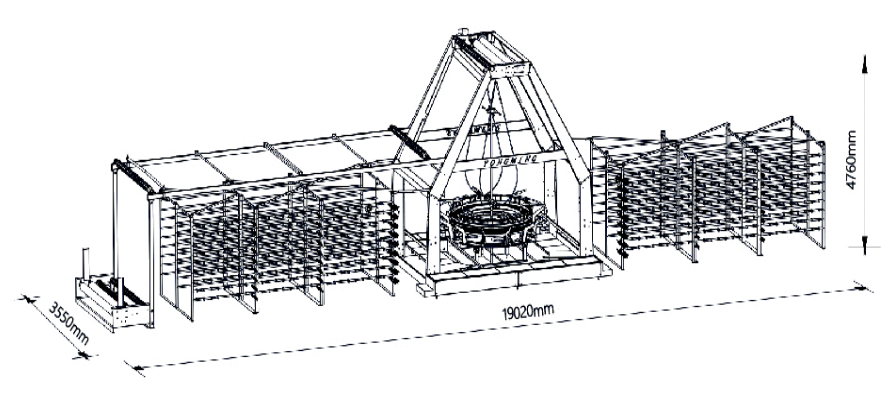

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

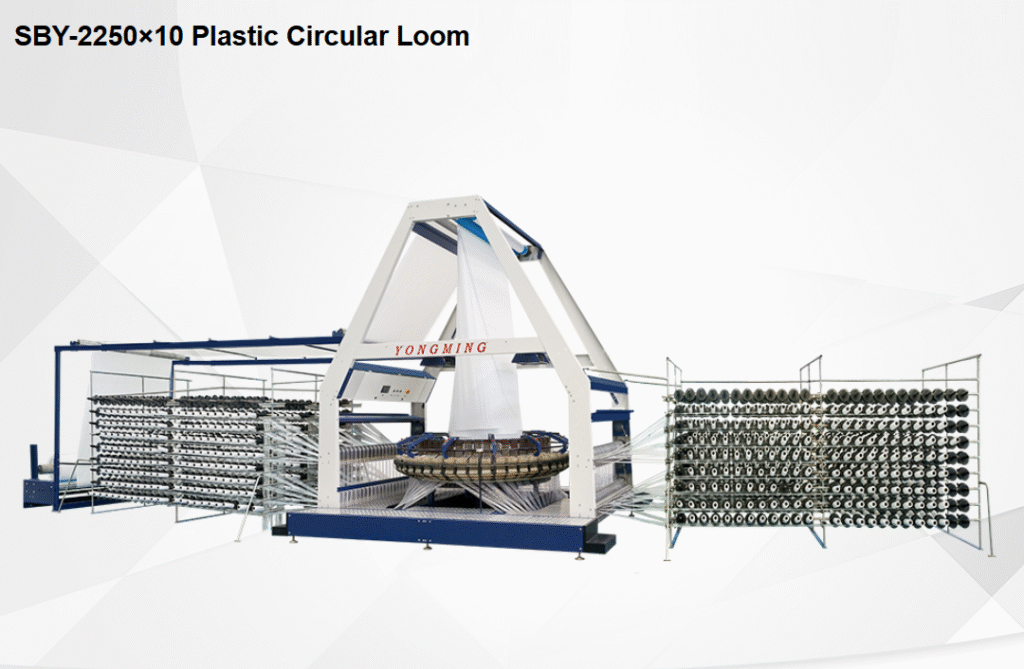

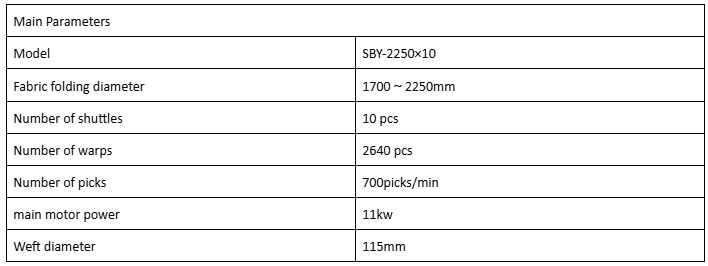

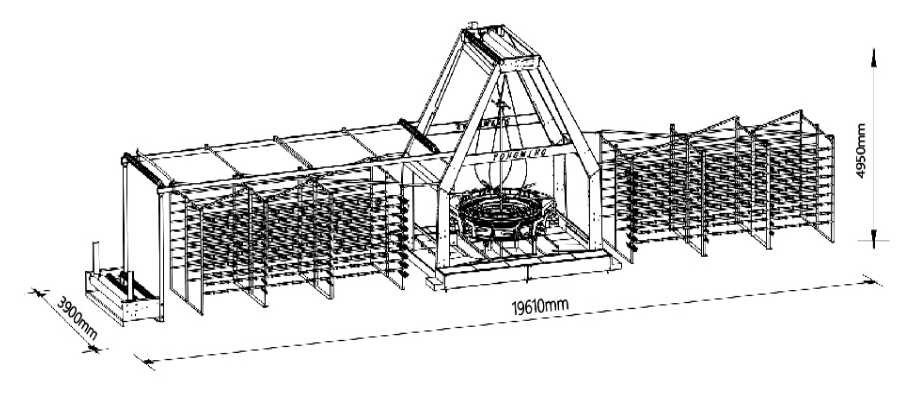

SBY-2250×10

- SBY-2250×10 Plastic circular loom is specially design for the high quality wide tube or flat fabric by PP or HDPE Available : Jumbo Bag, Tarpaulin Geo Textile, etc

- Plate cam with Grommet band & heddle wire structure, running stable, low noise, low consumption and high efficiency

- Weft break & end detecting system

- Warp feed system

- HMI central control, easy operation

Human-Machine Interface

Main motor, fabric lifting motor, and warp feeding motor adopt inverter control. The advanced HMI ensures smooth operation, precise adjustment, and user-friendly handling.

Warp Feeding System

Designed to adjust warp tension on both sides according to fabric weight. This minimizes weaving width variations, ensuring consistent quality and stable performance.

Weft Breakage & Finished Detecting System

Breakage detection uses magnetic signals for accurate and reliable control. Finished detecting stops the loom automatically when the weft tape is nearly exhausted.

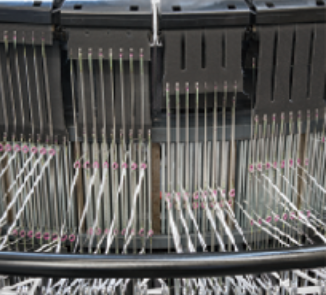

Grommet Band & Wire Heald Structure

Made of high-strength, durable materials combined with wire healds. Provides stable weaving performance, reduced noise, and long service life of the machine.

Parameters

Composed By

- Main Portion

- Creel Frame

- Warp Break Detecting System

- Weft Break Detecting System

- Central Drive System

- Fabric Take Up System

- Size Ring

- Control System

- Winder

- Warp Feed System

- = Standard

- Slitting And Expander

- Inner Line Film Unwinder

- Gesseting Device

- The Second Winder

- = Option

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.

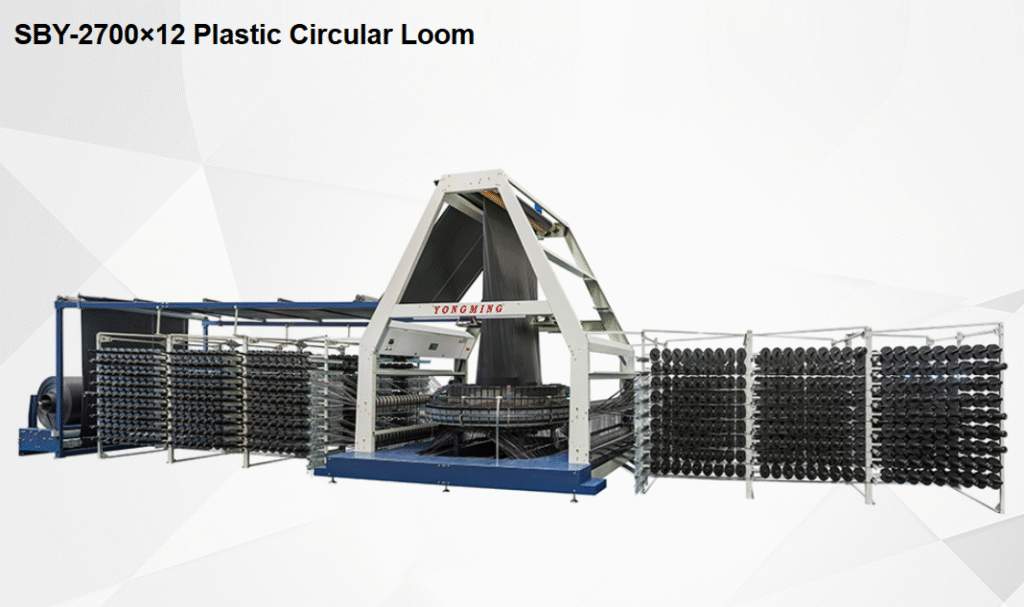

SBY-2700×12

- SBY-2700×12 Plastic circular loom is specially design for the high quality wide tube or flat fabric by PP or HDPE Available : Jumbo Bag, Tarpaulin Geo Textile, etc

- Plate cam with Grommet band & heddle wire structure, running stable, low noise, low consumption and high efficiency

- Weft break & end detecting system

- Warp feed system

- HMI central control, easy operation

Human-Machine Interface

Main motor, fabric lifting motor, and warp feeding motor adopt inverter control. The advanced HMI ensures smooth operation, precise adjustment, and user-friendly handling.

Warp Feeding System

Designed to adjust warp tension on both sides according to fabric weight. This minimizes weaving width variations, ensuring consistent quality and stable performance.

Weft Breakage & Finished Detecting System

Breakage detection uses magnetic signals for accurate and reliable control. Finished detecting stops the loom automatically when the weft tape is nearly exhausted.

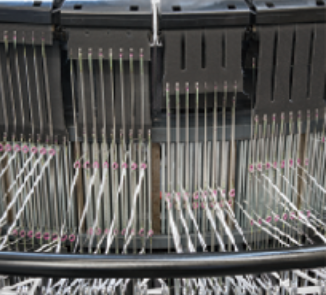

Grommet Band & Wire Heald Structure

Made of high-strength, durable materials combined with wire healds. Provides stable weaving performance, reduced noise, and long service life of the machine.

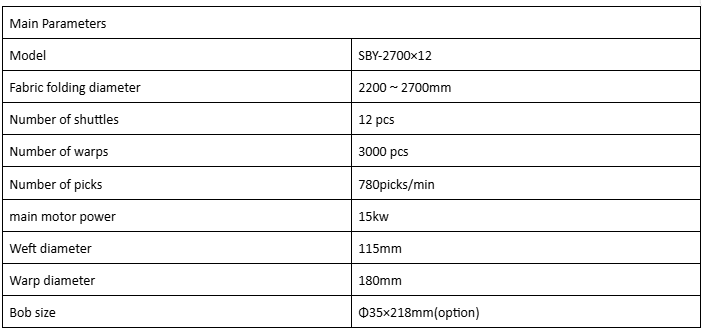

Parameters

Composed By

- Main Portion

- Creel Frame

- Warp Break Detecting System

- Weft Break Detecting System

- Central Drive System

- Fabric Take Up System

- Size Ring

- Control System

- Winder

- Warp Feed System

- = Standard

- Slitting And Expander

- Inner Line Film Unwinder

- Gesseting Device

- The Second Winder

- = Option

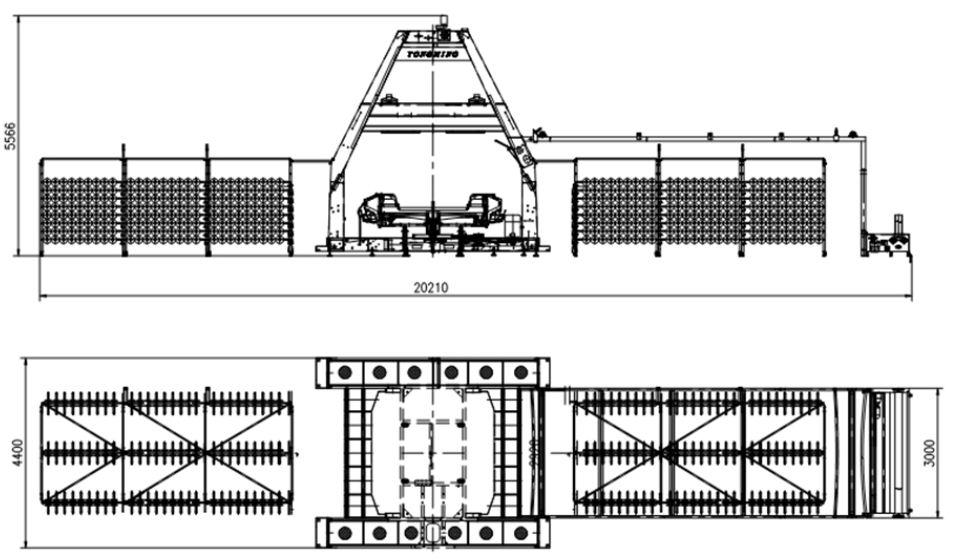

Size

Specification and dimensions are subject to change without prior notice. We always adhere to designing idea of high quality, high efficiency & low consumption, protect the environment and promote sustained development.